2 yrs

200 tons

5 years

22%

Due to ongoing maintenance issues, two chillers needed to be replaced in a two-building complex. The mechanical contractor followed the industry status quo and recommended a like-for-like replacement of the chillers (same tonnage with newer models). Uniquely, the two chillers were housed in the same building but piped to their respective buildings.

2 yrs

200 tons

5 years

22%

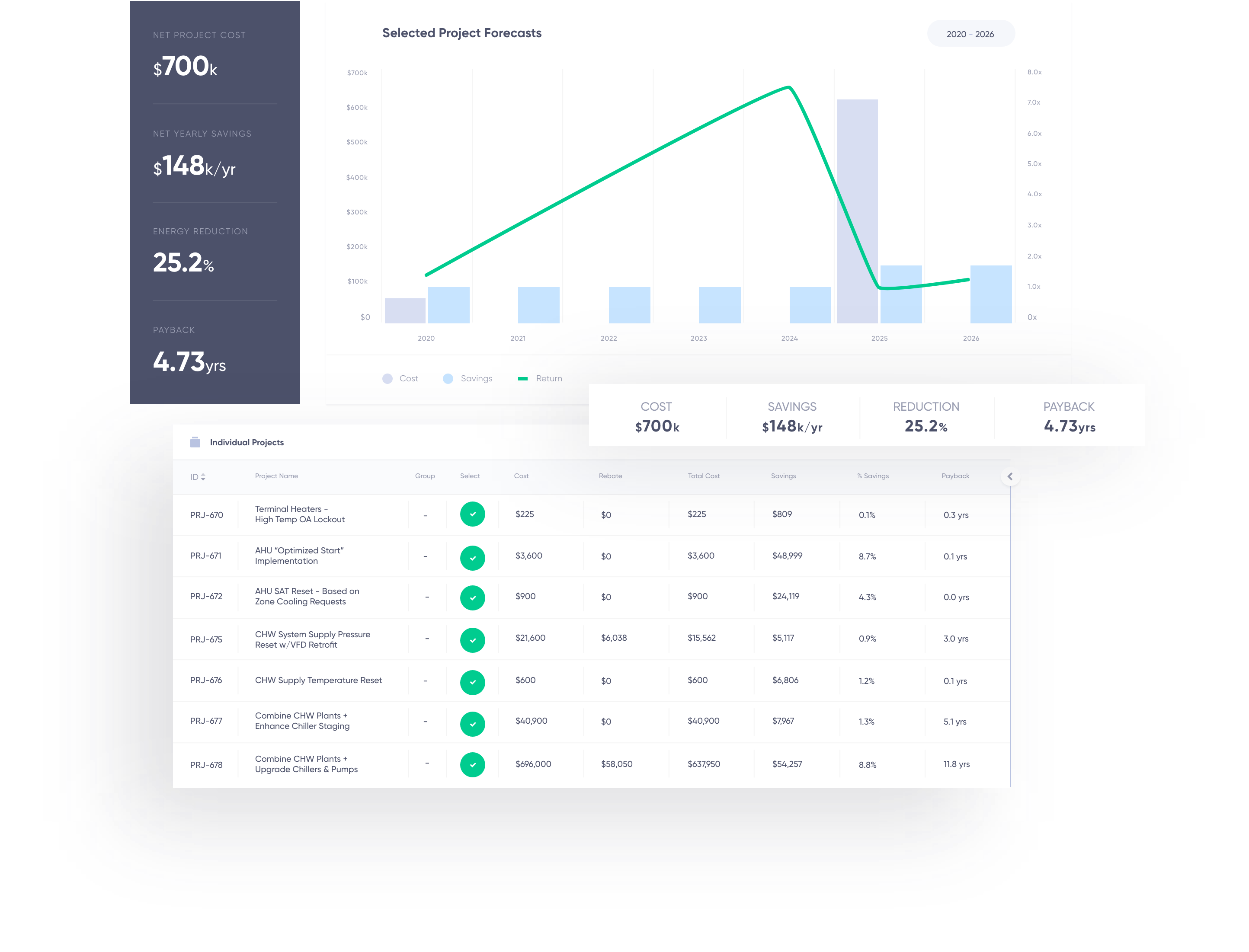

As part of Bractlet’s onboarding process, the capital plans for the two buildings were ingested into our software and analyzed. Our software and digital twinning process flagged the unique characteristic of the chillers being in the same building and in need of replacement. Leveraging a database of projects created from experience and data, Bractlet identified an opportunity to implement a more efficient, more resilient, and faster payback option than the solution the contractor had proposed to the customer. Using the Digital Energy Twin(TM) of the building, Bractlet simulated an alternative path for the client. Since the chillers were located in the same building, they could be piped together, which enabled the implementation of advanced control algorithms to optimize chiller staging for both energy and maintenance, while increasing resiliency of the entire two building system. Both the originally proposed solution by the contractor and the newly identified solution were simulated using the 98%+ accurate Digital Energy Twin of the buildings, allowing financial decision-makers to apply a consistent methodology in analyzing both options and confidently make the best decision for their buildings.

When coupled with other Bractlet identified control optimizations, the originally proposed solution would have decrease energy consumption for both buildings by 21%. Whereas, the alternative path identified by the Bractlet platform would save the building 43% on energy costs and payback in under 3-years — more than double the energy savings!

Traditional engineering firms do not have the capability of producing the analysis that Bractlet conducted for the customer with nearly the provided degree of accuracy and within the same timeframe. Not only is Bractlet’s Digital Energy Twin technology able to accurately simulate capital improvement projects, but it is also able to model advanced controls algorithms, giving building owners holistic intelligence in their decision-making.

02

YEARS REDUCED PAYBACK

22%

COST SAVINGS

200

TONS INCREASED TOTAL CAPACITY

Products that fit your budget and investment strategy.